If the WIP computation and value were incorrect, the plant may go out of balance, affecting delivery schedules and resulting in financial losses since fewer future sales would be made. The WIP inventory https://www.bookstime.com/articles/stale-dated-checks formula aids in performance monitoring by evaluating bottlenecks and operational efficiency. It also facilitates process optimization to enable enhancements in manufacturing processes.

Just in Time Procurement

Work in progress describes the costs of unfinished goods that remain in the manufacturing process, while work in process refers to materials that are turned into goods within a short period. The terms “work in progress” and “work in process” are used interchangeably to refer to products midway through the manufacturing or assembly process. When an item of inventory has been combined with human labour but has not yet attained the state of completed products, it is categorised as a WIP. There are several accounting techniques used by various firms to calculate WIP and other inventory accounts.

What is work in process (WIP) inventory? Definition, formula and benefits

While work in process and finished goods refer to various stages in an inventory’s life cycle, they have clear distinctions. For example, let’s consider an automobile manufacturing company that produces cars on an assembly line. The company uses a just-in-time (JIT) inventory system, meaning parts are only delivered to the assembly line when needed. Partnering with a 3PL such as Product Fulfillment Solutions can allow you to manage and view beginning inventory numbers, access demand forecasting tools, and gather data on inventory turnover.

Raw materials

Work-in-Process Inventory (WIP) is an essential aspect of inventory management in the manufacturing industry. WIP inventory represents the unfinished production of a company, and its efficient management can help reduce production costs, improve productivity, and maximize profitability. Overall, the role of WIP inventory in the supply chain is to help manufacturers optimize production processes, reduce costs, and improve efficiency. Work-in-process (WIP) inventory plays a crucial role in the supply chain, representing the goods being manufactured or assembled. It is a vital component of inventory management that helps ensure the production process runs smoothly and that a company produces products efficiently and cost-effectively. Many executives already have inventory management software deployed, but the reality under the surface is disappointing.

Before attempting to calculate your current WIP inventory value, here are some terms you will need to know first. But in order to build the optimal inventory management system, you need the right tools. Another reason to classify WIP inventory is that it’s a significant factor in the valuation of your business.

Production Best Practices for Work-in-Process Inventory

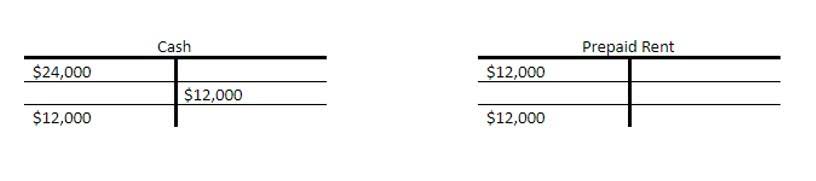

- The cost of goods flows to the income statement via the cost of goods sold (COGS) account.

- If you’re applying for a loan, the lender may be hesitant to count WIP inventory as collateral (even though it’s tallied as an asset) since it’s not very liquid.

- The terms “work in progress” and “work in process” are used interchangeably to refer to products midway through the manufacturing or assembly process.

- This can’t be done unless the systems has accurate data that precisely reflects the reality in your plant.

- Taking time to classify WIP inventory in a warehouse waiting to be assembled might seem tedious, but it’s crucial for monitoring and improving your supply chain and inventory control.

- ShipBob’s technology fully integrates with your store to easily manage all inventory and orders from one central dashboard while they fulfill your orders on your behalf.

- Consequently, utilizing inventory management software is an important aspect of effective inventory management.

Overestimating can result in producers paying huge taxes when they are not necessary, which is equally dangerous. For instance, a bakery producing 50 packets of bread or a company that makes mobile phones assembling various components for an order will be considered to what is an example of work-in-process inventory for an automobile company? have work in process. For example, a building whose five floors are to be constructed out of a planned twelve floors building is a WIP example. Renovation, tasks, and services can all be referred to as work in progress, which is more comprehensive than work in process.

- In hotels, customers use similar terminals to place orders for room service or to pay hotel bills.

- The weighted average method, or average cost method, deals with inventory utterly different from the FIFO and LIFO methods.

- Keeping accurate records allows you to identify patterns in inventory usage, such as seasonal fluctuations in demand, and adjust your inventory levels accordingly.

- By managing WIP inventory effectively, manufacturers can ensure that the production process runs smoothly and deliver the products to customers on time.

- Work in process refers to unfinished items that will soon be transformed into finished goods.

- Some organizations avoid the issue entirely by outsourcing any work that involves work-in-process inventory.

Sortly is an inventory management solution that helps you track, manage, and organize your inventory—from any device, in any location. We’re an easy-to-use inventory software that’s perfect for large or small businesses. Sortly builds inventory tracking seamlessly into your workday so you can save time and money, satisfy your customers, and help your business succeed.

- In addition, the market may be more willing to buy work in process goods outright if they are for standardized goods.

- When the inventory management software isn’t properly rolled out to support the business processes, the workarounds create an unnecessarily fragile system.

- For example, using barcodes and QR codes can improve the accuracy of inventory records and the speed at which those records can be updated.

- WIP inventory can also help to improve productivity by ensuring that they allocate the resources efficiently.

- The fastest and most affordable strategy to reduce WIP is to keep equipment in good condition.